With Congress’s recent $7.5 billion investment to expand EV charging infrastructure, numerous companies are now eyeing opportunities to enter the commercial EV charging station market—but if they don’t consider packaging and the supply chain they have no hope of competing with industry leaders.

Shipping large commercial electric vehicle (EV) charging stations requires planning and careful execution to ensure the equipment arrives safely and is ready for installation—and that all starts with packaging. Here are some tips on finding the right packaging solution for EV chargers.

1. Customize packaging

Not all EV charging stations are created equally so custom-designed packaging is key. Packaging should be tailored to the dimensions of the charging station and its components. This will minimize movement and shifting during transit and prevent damage.

2. Use protective cushioning

In addition to custom-sized packaging, use the proper cushioning in the interior of the package. Materials commonly used are PE foam and custom corrugated board and others that can absorb shocks and vibrations.

3. Secure sensitive components

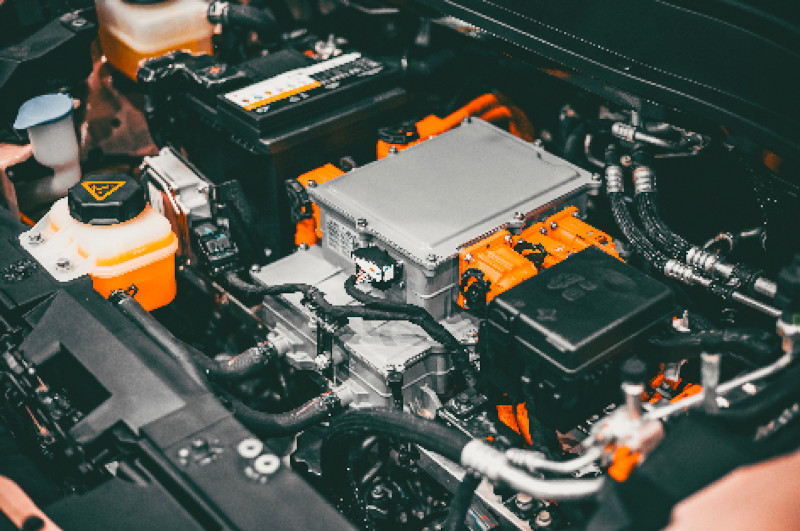

EV charging stations contain many sensitive—and expensive—electrical components that need to be secured properly. Protective cushion curve packaging and ElectroStatic Discharge bags or other solutions are highly recommended.

4. Design for quick installation

The charging station should be packaged in a way that makes it easy to unbox and install. Companies do not have time to waste figuring out complicated packaging – these stations are a significant investment and clients want to start seeing returns as soon as possible!

5. Cube out

Commercial EV charging stations are often transported as freight using freight carriers that can accommodate heavier loads. Freight shipping may involve less-than-truckload (LTL) or full-truckload (FTL) shipments depending on the size and quantity of charging stations. However, it is ideal to design packaging optimized for space or “cubing out.” Misuse of space leads to expensive damage and delays in the supply chain.

6. Crates are also an option

Consider using custom crates, especially for particularly large or heavy charging stations. Custom crating provides additional structural support while minimizing movement.

7. Palletization

Charging station components can be secured on pallets for ease of handling and transportation. This helps in efficient loading and unloading, especially when using forklifts or pallet jacks. Ease of movement through the supply chain is imperative.

8. Consult the data

Finding the ideal packaging for EV charging stations can be trial and error. But to reduce those errors, perform a packaging audit to gather data about where your current packaging may be underperforming. An audit is especially helpful if you have a limited budget because you’ll be able to tackle the most pressing issues first.

9. Entrust packaging design to the professionals

The packaging requirements for commercial EV charging stations differ considerably from consumer-grade units intended for at-home use. Commercial packaging demands a higher technical proficiency, more attention to detail, and a comprehensive understanding of the entire supply chain. Collaborating with packaging experts ensures a faster turnaround, prevents costly errors, and secures better pricing on materials.

For enhanced packaging efficiency, PCD is here to help. We specialize in innovative, custom packaging design and have experience working with EV charger manufacturers. Our North American footprint means we’re able to assist you wherever you are… Mexico, Canada or the United States. Feel free to reach out with any questions – we’re here to help. contact us!