A myriad of internal and external factors can contribute to supply chain disruptions. These disruptions can be costly, time consuming, and inconvenient. Prepare yourself to for these disruptions before they even occur. 4 solutions for supply chain disruptions are as follows:

#1 Utilize Protective Packaging Concepts:

Protective packaging concepts exist with the sole purpose of securing an item in place. With the help of materials like bubble wrap, corrosion inhibitors, inflatable space fillers, foam, paper, and shrink wrap, it’s possible to make an item nearly impervious to external contaminants. Protective packaging concepts also allow distributors to effectively secure an item during shipment. For packages that have a long journey, this step is vital to the protection of your shipment.

#2 Conduct Packaging Audits:

With the help of experts, it’s possible to identify potential packaging issues before they occur. Packaging engineers are more likely to observe potential threats in advance, and an audit allows businesses to cut down on those threats. This process allows manufacturers to operate more effectively by reducing the amount of time that’s spent on damaged shipments. This process can also help you to evaluate the look of your packaging, and to reduce the amount of time that’s wasted on the packaging process.

#3 Size Packaging Correctly:

If there is too much space or not enough space in a shipment, there’s an increase in damage potential. Shifting during shipment can dislodge sensitive parts, or even permanently damage components. Measuring an item can help you to determine the best packaging size for an item. But it’s also important to use those protective packaging items like films and fillers to give your shipment a shock-barrier.

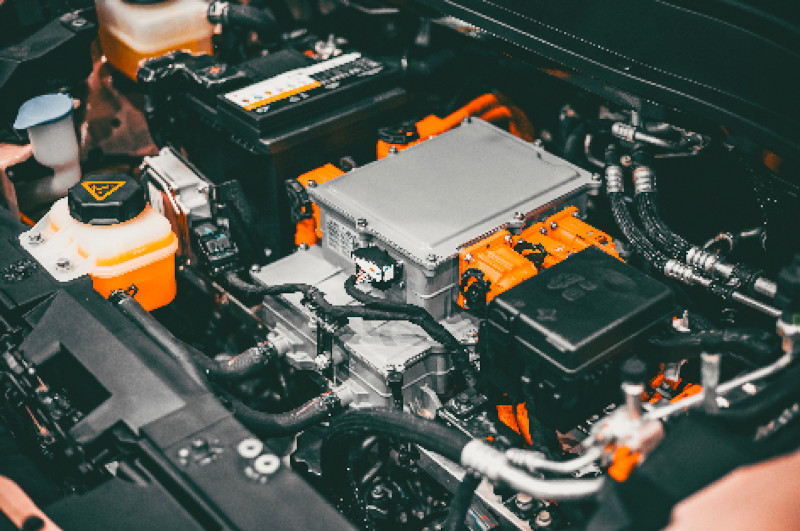

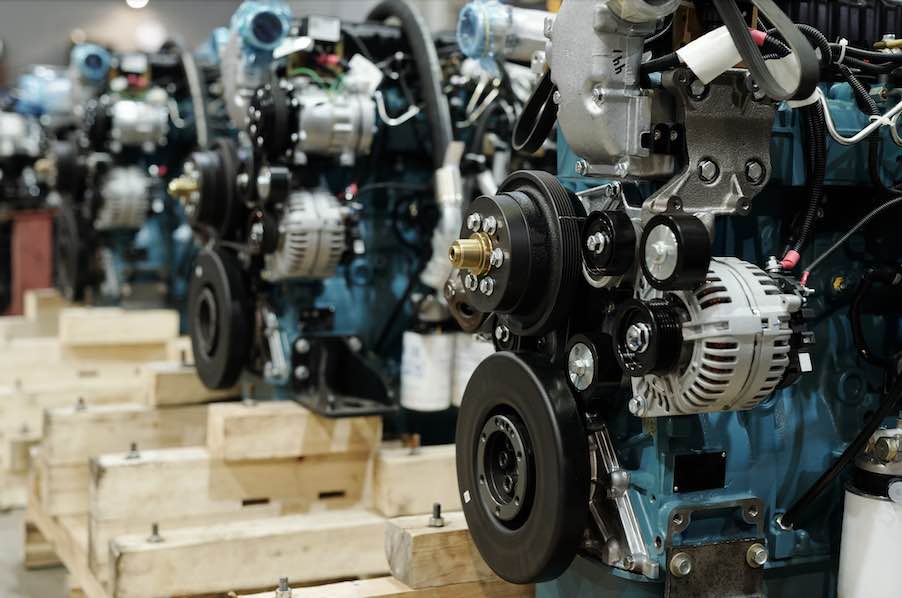

#4 Consider Using Creative Packaging Concepts:

Implementing creative packaging concepts allows each brand to increase a shipment’s efficiency and protective nature. But they may also be eye-catching and designed to draw your customers’ attention. Depending on the item that’s being shipped, using steel racks to secure a shipment may be another possible option. Steel racks are generally used for large and heavy parts. For this reason, many automotive manufacturers rely on steel racks because of their ability to securely carry heavy loads. Custom shipping crates are another option that provides heightened strength and protection. Utilizing this system can allow you to reduce the labor and time that’s spent shipping large and bulky items.

For more information on how PCD can help you overcome supply chain disruptions, contact us!