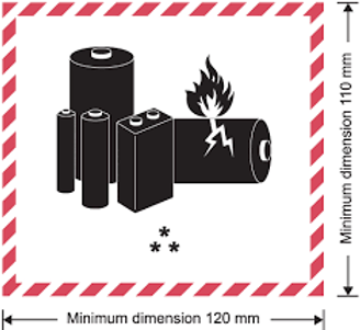

The U.S. Department of Transportation’s (DOT’s) Hazardous Materials Regulations (HMR; 49 C.F.R., Parts 171-180) classifies lithium ion batteries as hazardous materials.

So, shipping them can get complicated.

DOT has specific packaging specifications, and there are many other factors to consider when choosing and designing packaging for lithium ion batteries. To find the right solution, several influencers will define the packaging materials and system you’ll need.

You MUST Consider the Shipping Materials Allowed by the U.S. Government

All lithium ion batteries must be shipped in a manner that protects against:

1. Short circuits

2. Movement within the outer package

3. Accidental activation of the equipment

As a general standard, lithium ion batteries may not be packaged in metallic inner packaging. Inner packaging must completely enclose each battery or cell, as they cannot make contact with other equipment or any other conductive material.

The inner packaging containing the lithium ion batteries may be placed in a container made from the following materials:

-

Metal, wooden, fiberboard or a solid plastic box

-

Metal, wood or plastic drum

-

Metal or plastic jerrycan

Lithium ion batteries that weigh more than 26.5 pounds and have a strong, impact-resistant outer casing, may be packed in strong outer packaging or in protective enclosure casings, like fully enclosed or wooden slatted crates, on pallets or other handling devices.

A rule of thumb is that lithium ion batteries must be packaged to prevent movement or contact with other materials

Each package MUST display the hazard communication label.

Consider the KIND of Lithium Ion Battery

Is your battery being shipped for recycling or disposal? Is it a prototype battery or damaged battery? Each kind has different specifications and packaging requirements.

Batteries for Recycle or Disposal: These batteries are exempt from testing and record-keeping requirements. They must meet typical packaging requirements for lithium ion batteries.

Prototype Batteries: Prototype lithium ion batteries are also exempt from testing and record-keeping requirements They must meet typical packaging requirements for lithium ion batteries in addition to:

-

The option of using non-combustible, non-flammable cushioning to prevent vibration and contact with other materials.

-

Batteries weighing more than 60 pounds must be contained in individual packaging.

-

Shipping papers must include the verbiage: “Transport in accordance with §173.185.”

Damaged or Recalled Batteries: Damaged lithium ion batteries may only be transported by highway, rail or vessel. Each battery must be placed in individual, non-metallic packaging. The inner packaging MUST be made of cushioning material that is non-combustible, non-conductive and absorbent.” The individual packaging must be contained by outer packaging made from the following materials:

-

Metal, wooden or solid plastic box.

-

Metal, plywood, or plastic drum.

The outer packaging must display the verbiage: “Damaged/defective lithium ion battery” and/or “Damaged/defective lithium metal battery.”

Finding the Perfect Solution

As you can see, shipping and packaging lithium ion batteries is complex because it is a heavily regulated item. While plenty of information exists about shipping requirements, how to design lithium ion battery packaging is a bit of a gray area. Don’t be shocked if it takes a few tries to have your designed certified, it can be a lengthy and frustrating process. Trial and error isn’t the easiest road to take, but working with the right packaging solution provider can ease this burden.

That’s where we can help.

We have extensive experience designing packagingthat meets the U.S. Government’s shipping specifications while also meeting our clients’ unique needs. If you’d like to learn more about how we can help solve your lithium ion battery packaging problems, don’t hesitate to contact us!